The Stratograph

A kinetic sculpture, and component of the Science Museum of Minnesota's

"Playing With Time" traveling exhibit.

-- Concept: at each venue, the piece creates a "core," a tube

filled with colored sand which is slowly deposited over a 3 month period.

The sand patterns depict both text and graphics relevant to the venue locale,

as well as an actual record in time of a physical phenomenon occurring

within the Stratograph's immediate environment.

June 7, 2002

I met Randy early this morning to change out the completed

tube, and start the second plot. Everything went smoothly, and PWTTUBE1.R8

is underway-- completion date 8/25 (79 days). During the process,

I loaded a newer version of the controlware (strato5.exe) which has some

added error checks (no Z moves, too many Z moves, plot height vs. plot

completion correlation). I also copied the log file from the completed

plot. It shows a faithful recording of

all the sand pixels dropped during the plot (up until the vandal-induced

interruption).

May, 2002

Everything was going well until 5/18, when apparently

a fairly tall visitor decided to vandalize the sand valve assembly by pulling

the spring mount off the black sand valve. This resulted in the

dumping of black sand until the tube was full. I was informed

two days later that the funnel was "buried under sand , and the machine

was not functioning." Although rather annoying, the remedy was simple:

I moved the top assembly, vacuumed the sand above the funnel, thereby freeing

it. After bringing the funnel up and removing it, I could then vacuum

down to the undisturbed level (in Hubert's forehead). This done,

I sent the funnel back down, replaced the head, and loaded up the remaining

portion of the plot (the Minnesota state map).

April, 2002

_

_ 23

days since the opening, and all is well. Visitors appear to be genuinely

engaged, and despite the lack of finished signage, many seem to be "getting"

it. The only unexpected finding has been that the archived tube has

settled an additional ~1/2"-- undoubtedly due to visitors moving it back

and forth. This raises the need for a threaded plug on the top wood

block, which will allow periodic "topping off" with black sand.

23

days since the opening, and all is well. Visitors appear to be genuinely

engaged, and despite the lack of finished signage, many seem to be "getting"

it. The only unexpected finding has been that the archived tube has

settled an additional ~1/2"-- undoubtedly due to visitors moving it back

and forth. This raises the need for a threaded plug on the top wood

block, which will allow periodic "topping off" with black sand.

March, 2002:

Actualization time:

Steel

bases and connecting structure cut.

Steel

bases and connecting structure cut.

Calibrations.

Calibrations.

Opening

day.

Opening

day.

February, 2002:

2/1

-

-  The

final design of the Stratograph is taking shape, as fabrication begins

with a trip to Youngblood lumber, and the choosing of ~100 board-feet of

Honduras mahogany. After gluing up the

active chamber's side panels, it was time to refine

some tool paths, and fire up the CNC router-- crucial for the tight

fit needed at the core tubes' ends, as well as the structural

integrity of the sand delivery assembly. Mark Balboa, of Balboa

Plastics, in Richfield, was extremely helpful with the acrylic fabrication--

selling me the small quantity of 1/4" sheet I needed, and lending me a

table saw blade optimized for acrylic.

The

final design of the Stratograph is taking shape, as fabrication begins

with a trip to Youngblood lumber, and the choosing of ~100 board-feet of

Honduras mahogany. After gluing up the

active chamber's side panels, it was time to refine

some tool paths, and fire up the CNC router-- crucial for the tight

fit needed at the core tubes' ends, as well as the structural

integrity of the sand delivery assembly. Mark Balboa, of Balboa

Plastics, in Richfield, was extremely helpful with the acrylic fabrication--

selling me the small quantity of 1/4" sheet I needed, and lending me a

table saw blade optimized for acrylic.

January, 2002:

1/19

It's

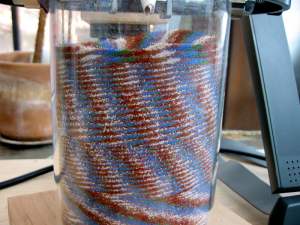

been about 3 weeks since "on the floor" testing began. Overall, the

Stratograph's behavior has been as I expected. And the response has

been good. The last run was an attempt to reproduce the Vikings and

Twins' logos. The relative success

and failure give me a good clue as to the

necessary size required for clear recognizability. Testing has provided

much useful information-- and produced an interesting

totem.

It's

been about 3 weeks since "on the floor" testing began. Overall, the

Stratograph's behavior has been as I expected. And the response has

been good. The last run was an attempt to reproduce the Vikings and

Twins' logos. The relative success

and failure give me a good clue as to the

necessary size required for clear recognizability. Testing has provided

much useful information-- and produced an interesting

totem.

1/11

Mona's

almost complete (laptop screen shot).

She's a bit fuzzy, but still recognizable-- especially

from

afar. This suggests that faces will need to fill at least 150x

150 or so pixels to be recognizable. The motion sensor recording

continues

to function well.

Mona's

almost complete (laptop screen shot).

She's a bit fuzzy, but still recognizable-- especially

from

afar. This suggests that faces will need to fill at least 150x

150 or so pixels to be recognizable. The motion sensor recording

continues

to function well.

1/9

Front:

Back:

CAD

drawing

CAD

drawing

The final form of the piece is taking shape.

Features of this design:

By utilizing two "display wings," the active center chamber

is stabilized without the need for a floor plate extending under the viewing

area directly in front.

The center chamber is enclosed by acrylic sheets front and

back; the four archived tubes are mounted on lazy-susans, allowing viewers

to handle and examine them.

The entire sculpture will disassemble into four main pieces:

The center chamber + steel base (1/4" thick), the two wings and their bases,

and the top reservoir assembly.

The CAD drawing lists pertinent dimensions. The

renderings are intended to give a feel for the overall appearance of the

completed work, but to save time I did not create different maps for the

archived tubes, or try to finesse the appearance of the wood grain.

Despite the light wood materials used throughout the exhibit, I have chosen

a dark hardwood (Honduras mahogany) for a variety of reasons-- both practical

and aesthetic.

1/8

Since

changing back to the 3M aggregate on 12/29, the Stratograph has been steadily

dropping sand at a rate of every ~7 seconds-- the actual rate which will

fill a core tube in 3 months time. For the most part, its behavior

has been what I expected-- nightly black bands, interlaced with daily activity

records. Close inspection of the record reveals some interesting

findings-- one of which is that the occasional blue bands seen during the

middle of the night are likely due to a late night cleaning crew.

One glitch which I believe is related to a timing routine error on my part

(since corrected) resulted in the complete absence

of activity recording during New Year's Day. No problems since

the fix. Today, the Stratograph is about midway through a plot of

the Mona Lisa (on the flip side of the activity record) -- expected to

be complete on 1/12.

Since

changing back to the 3M aggregate on 12/29, the Stratograph has been steadily

dropping sand at a rate of every ~7 seconds-- the actual rate which will

fill a core tube in 3 months time. For the most part, its behavior

has been what I expected-- nightly black bands, interlaced with daily activity

records. Close inspection of the record reveals some interesting

findings-- one of which is that the occasional blue bands seen during the

middle of the night are likely due to a late night cleaning crew.

One glitch which I believe is related to a timing routine error on my part

(since corrected) resulted in the complete absence

of activity recording during New Year's Day. No problems since

the fix. Today, the Stratograph is about midway through a plot of

the Mona Lisa (on the flip side of the activity record) -- expected to

be complete on 1/12.

December, 2001:

Dec. 31

Stopped by the Museum this morning, and found that the

theta axis set screw had worked its way loose sometime last night.

So, while the theta motor was working fine, the tube was not rotating.

Also, found that the new, fine sand was sticking to the sides of the core

tube, and was prone to producing an uneven sand layer. Decided

to return to the 3M aggregate-- loaded the reservoir tubes, and started

testpat.r8 (60,000 pixels) over again. Should complete on 1/4/02.

Dec. 29

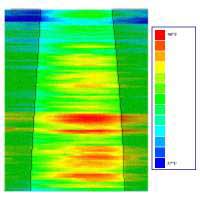

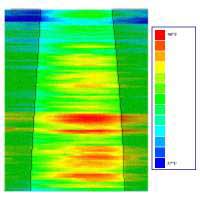

The

first day's worth of data recording shows pretty much what I expected--

about 3/4" of added height, with lots of red during the early part of the

day, tapering to green and blue, then black over night.

The

first day's worth of data recording shows pretty much what I expected--

about 3/4" of added height, with lots of red during the early part of the

day, tapering to green and blue, then black over night.

Dec. 28

The

prototype is up and running at the Museum, as of this morning. Using

the protective display case that Dan was able to dig up, it is nestled

under the staircase on level 3, facing the main thoroughfare to "the bones"

(paleo). I met with Dan, Randy, Russ and Richard and explained the

key features of operation. To begin with, we will use a small test

image (testpat3.r8, which contains the Museum logo), and spread it over

5 days. This is approximately the same rate that would fill the entire

tube in 3 months. The Museum is packed with holiday visitors today,

and I anticipate a fair amount of red sand. The PIR sensor is currently

located about 8' up, and looks down and in front of the case.

The

prototype is up and running at the Museum, as of this morning. Using

the protective display case that Dan was able to dig up, it is nestled

under the staircase on level 3, facing the main thoroughfare to "the bones"

(paleo). I met with Dan, Randy, Russ and Richard and explained the

key features of operation. To begin with, we will use a small test

image (testpat3.r8, which contains the Museum logo), and spread it over

5 days. This is approximately the same rate that would fill the entire

tube in 3 months. The Museum is packed with holiday visitors today,

and I anticipate a fair amount of red sand. The PIR sensor is currently

located about 8' up, and looks down and in front of the case.

Dec. 26-27

Continued

testing of the PIR sensor and new software changes. Also, samples

of colored sand from Dick Blick's web store

have arrived. They carry a wide variety of brightly colored sands,

and the price is not dramatically more than the 3M aggregate. It

is, however, much finer-- which may add to the resolution capabilities,

but definitely makes it more difficult to actually see the sand come out

of the spout.

Continued

testing of the PIR sensor and new software changes. Also, samples

of colored sand from Dick Blick's web store

have arrived. They carry a wide variety of brightly colored sands,

and the price is not dramatically more than the 3M aggregate. It

is, however, much finer-- which may add to the resolution capabilities,

but definitely makes it more difficult to actually see the sand come out

of the spout.

In order for me to transport the Stratograph to the Museum,

without spilling the first tube's sand, I have fashioned a plunger.

It appears to work just fine.

Dec. 19-21

_

_  Focus

has turned toward a major overhaul of the Stratograph software. I've

run into several annoying bugs-- from simple oversights, to subtle problems

dealing with numerous timing routines. As always,

the

sand records my progress (or lack thereof). My first attempt

at mapping motion detector data to colors turned out to be too insensitive

(mostly black). The scheme I am now using (strato4.exe) produces

more color deposition. It is difficult to mimic random visitor motion.

I tried locking my dogs in the room when I was out, but it appears that

they both took naps (lots of blue and black). Close

inspection does reveal a correlation between inactivity and night--

in this case, the nocturnal black band is about 4x thicker than would be

expected in an actual 3 month plot, since I am running at about 4x speed).

As expected, text and graphic quality are

far better when reproducing horizontal lines than vertical.

Focus

has turned toward a major overhaul of the Stratograph software. I've

run into several annoying bugs-- from simple oversights, to subtle problems

dealing with numerous timing routines. As always,

the

sand records my progress (or lack thereof). My first attempt

at mapping motion detector data to colors turned out to be too insensitive

(mostly black). The scheme I am now using (strato4.exe) produces

more color deposition. It is difficult to mimic random visitor motion.

I tried locking my dogs in the room when I was out, but it appears that

they both took naps (lots of blue and black). Close

inspection does reveal a correlation between inactivity and night--

in this case, the nocturnal black band is about 4x thicker than would be

expected in an actual 3 month plot, since I am running at about 4x speed).

As expected, text and graphic quality are

far better when reproducing horizontal lines than vertical.

Tentative plan is to set up the prototype at the Museum

next week.

Dec. 13-14

After

destroying two $7 security lights from Home Depot without much success,

I was able to hack into the circuitry of

a PIR security module being sold at AxMan for $10. Two of the three

PIR devices I ordered from MPJA arrived on 12/12-- far easier to deal with!

I spent most of yesterday writing a program that will allow testing and

logging of the "hit rates" form three sensors simultaneously. I had

two sensors hooked up (AxMan's, and MPJA-1) by 10pm and started recording.

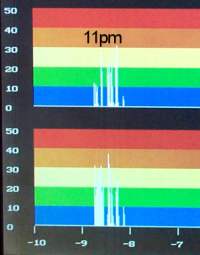

The "triple chart" shows the motion detection hit rates for these two (

the top chart is me messing with the unconnected input wire for sensor

#3). As expected, both sensors remained unactivated over night, until

this morning. The vertical scaling numbers refer to the number of

times per minute that the sensor was activated (the software checks the

status every second). Each PIR module has different latency times--

hence, although 60 hits / minute is the absolute max-- far lower numbers

are expected, even when there is relatively constant motion in the sensing

area. Each vertical bar (one pixel wide) represents 1 minute.

After

destroying two $7 security lights from Home Depot without much success,

I was able to hack into the circuitry of

a PIR security module being sold at AxMan for $10. Two of the three

PIR devices I ordered from MPJA arrived on 12/12-- far easier to deal with!

I spent most of yesterday writing a program that will allow testing and

logging of the "hit rates" form three sensors simultaneously. I had

two sensors hooked up (AxMan's, and MPJA-1) by 10pm and started recording.

The "triple chart" shows the motion detection hit rates for these two (

the top chart is me messing with the unconnected input wire for sensor

#3). As expected, both sensors remained unactivated over night, until

this morning. The vertical scaling numbers refer to the number of

times per minute that the sensor was activated (the software checks the

status every second). Each PIR module has different latency times--

hence, although 60 hits / minute is the absolute max-- far lower numbers

are expected, even when there is relatively constant motion in the sensing

area. Each vertical bar (one pixel wide) represents 1 minute.

Dec. 10

Finalizing

design of top assembly. CAD layout.

Also, finalizing electronics: schematic,

PCB

layout, circuit board under construction.

Finalizing

design of top assembly. CAD layout.

Also, finalizing electronics: schematic,

PCB

layout, circuit board under construction.

Awaiting PIR sensor from MPJA-- should be here tomorrow.

Dec. 5

Conference call with Robert, Katrina, Bob and myself--

"Plan A" (multiple buttons corresponding to sand colors as input) vs. "plan

B" (single button or sensor, sand color related to "hit rate") discussed.

Plan B favored. Sensor (passive detection) vs. active input-- passive

favored. Will proceed with current plans to use 24 hr/day, metronomic

sand drops.

Have begun to experiment with PIR sensors. Bought

a $7 security light at Home Depot, and hacked the sensor board.

Have ordered a variety of PIR

modules from Marlin P. Jones, but the bare sensor is on back order.

Also, have found a couple articles on hacking this sensor --

Jack Dollhausen's; Seattle

Robotics'

Dec. 3

Rendered tube front, back,

animation

(682K mov)

Rendered tube front, back,

animation

(682K mov)

After much thought, have decided to try going back to

an interactive approach for the "data driven" aspect. Key reasons:

-

Use of archived temperature data is not as "natural" as recording

phenomena from local environment.

-

Aesthetic promise of temperature data questionable.

-

lack of interaction at night will create recognizable, and

visually pleasing, bands representing a 24 hour period.

Schema:

Each venue will have its own "template" of preordained

sand pixels. These will include the site's name, logo, and bitmaps

of locally recognizable shapes and faces. These pixels (composed

of black and white sand) cannot be changed by interaction, but will comprise

the minority of the filled tube's pixels. Non-preordained pixels

can be modified by visitor interaction as follows: there will be

buttons (one for each sand color other than B & W) which the visitor

can push. If button #1 is pushed, color #1 is added to the "queue"

The queue is a portion of a computer monitor which is visible through a

rectangular porthole, and is composed of colored "bricks." Every

6 to 7 seconds, a sand pixel is released-- the sand color is governed by

the color at the bottom of the queue. If nobody interacts with the

buttons, the queue stays filled with black "bricks." Interaction

with the buttons replaces the black bricks with chosen colored bricks.

After each sand pixel drop, the bottom brick disappears, and the stack

of bricks moves down one. If the visitor interacts "vigorously" with

the buttons, then the queue fills to some maximum value, and will not accept

any more bricks, until a sand pixel is dropped-- freeing up one slot.

Visualization images above, while crude, give at least

some idea of what the filled tube will look like. In this case, interactive

sand pixel colors were chosen randomly, with random repeats. The

palette is my best approximation of the five non-black/white 3M sands that

I have:  .

.

The visualizations do not yet show the "queue," the sand

valves and storage on top, or the interactive input buttons. Also,

to be added are the archived tubes from prior venues on display.

Assuming: Tube length

of 72", 100 day duration, 24 hr/day operation, similar sandpixel size to

what I've been doing (12ms open time)--

Time

between pixels = 6.7 sec.

3/4"

/ day

13000

pixels / day

400

pixels per rotation (row)

32

rows / day

1.3

megapixels / venue -- (entire record would fit nicely on a floppy)

November, 2001:

Nov. 26

A

key point in contemplating the building a second stratograph, is the final

form of the traveling unit. From the meeting on 11/19, we have decided

to pursue a "monolithic" strategy-- the tube and all moving parts will

be encased in acrylic. I've begun to visualize this design-- the

base will be fabricated from 1/2" steel, and will weigh ~300lbs, as shown.

The sides and top are 1.5" Honduras mahogany. The front and back

acrylic panes are 1/4".

A

key point in contemplating the building a second stratograph, is the final

form of the traveling unit. From the meeting on 11/19, we have decided

to pursue a "monolithic" strategy-- the tube and all moving parts will

be encased in acrylic. I've begun to visualize this design-- the

base will be fabricated from 1/2" steel, and will weigh ~300lbs, as shown.

The sides and top are 1.5" Honduras mahogany. The front and back

acrylic panes are 1/4".

Nov. 20

An

example of Bob's early experiments with visualizing data (in this case,

temp and daylight hours). Also, a rendering

of the pattern mapped upon a cylinder.

An

example of Bob's early experiments with visualizing data (in this case,

temp and daylight hours). Also, a rendering

of the pattern mapped upon a cylinder.

Nov. 19

Met with Robert, Dan and Katrina at my place, while stratograph

continued to drop sand. Salient points:

-

Robert raised the importance of a "data-driven" aspect to

the piece as a direct link to the idea that there is a direct connection

to time. We all agreed. One potential strategy would be to use half

the tube for this, and half for text or bitmap information.

-

One potential source of data could be weather-- temp and

precip. We could use almanac data (Katrina), to avoid real time data

entry compliance issues.

-

We'll try to test various strategies using the visualizing

tools Bob is developing.

-

The favored barrier system for the final version has shifted

from a railing system to acrylic / glass plates in front and behind that

will allow viewers a closer look.

-

Dan would like to get the prototype out on the floor as soon

as possible. I agree-- but want to make sure we can test pattern

ideas quickly. I am considering the possibility of building

a second machine.

Nov. 13

Spurred

on by the successes with simple text, I turned to the next level of complexity.

Choosing simple images of my daughter's face and my own, I attempted to

do them in sand. Unfortunately, I had made a small (but dumb) error

in my program, which caused a slight shift in alignment with each row.

I discovered the error upon awaking (11/11) and finding what I hoped would

be faithful renditions, smeared to the left. After correcting this

bug, I began again. Now 28 hours into what will be a 41 hour plot,

the results are telling.

Spurred

on by the successes with simple text, I turned to the next level of complexity.

Choosing simple images of my daughter's face and my own, I attempted to

do them in sand. Unfortunately, I had made a small (but dumb) error

in my program, which caused a slight shift in alignment with each row.

I discovered the error upon awaking (11/11) and finding what I hoped would

be faithful renditions, smeared to the left. After correcting this

bug, I began again. Now 28 hours into what will be a 41 hour plot,

the results are telling.

Nov. 11

A

little more ambitious-- tried doubling to 192 pixels/row, and more difficult

text. Not bad (3 hours, 25 min.

to complete, settings: valve open 30 msec, closed 1500 msec). To facilitate

this evaluation, have moved programming platform to C (stratro1.exe). Can

now load bitmaps, adjust solenoid timings, and pause plot to adjust parameters.

A

little more ambitious-- tried doubling to 192 pixels/row, and more difficult

text. Not bad (3 hours, 25 min.

to complete, settings: valve open 30 msec, closed 1500 msec). To facilitate

this evaluation, have moved programming platform to C (stratro1.exe). Can

now load bitmaps, adjust solenoid timings, and pause plot to adjust parameters.

Nov. 10

Having

a reliable sandlevel-following apparatus, I returned focus upon feasibility

of reproducing bitmap images. Starting with 96 sanddump pixels per

revolution, I tried my first test image-- my

illustrious initials, which turned out upside down and backwards.

Naturally.

Having

a reliable sandlevel-following apparatus, I returned focus upon feasibility

of reproducing bitmap images. Starting with 96 sanddump pixels per

revolution, I tried my first test image-- my

illustrious initials, which turned out upside down and backwards.

Naturally.

Nov. 9

While the initial sand sensor circuitry appeared to work

well, as night fell, it became clear that ambient light conditions had

a marked effect. This appears due to the relatively weak IR signal

coming from the LED. To increase the "signal to noise ratio," I decided

to abandon the LED in favor of a visible laser

diode (using a hacked keychain laser pointer). Substituting the

pointer's three watch batteries with my 5 volt supply, knocked down to

~3.2V via diodes, it works just fine. The tight light spot raises

the potential for misalignment, so I spread the beam using a hemispherical

plastic lens. Initial tests (over night) worked perfectly. New

schematic.

Nov. 8

Focused

upon instituting sand sensing. Used IR LED and phototransisitor similar

to Pipedream II. Had to add amplification in order to ensure enough

"distance" between light and dark. Used

empiric

method to discern optimal resistor values. Schematic.

Focused

upon instituting sand sensing. Used IR LED and phototransisitor similar

to Pipedream II. Had to add amplification in order to ensure enough

"distance" between light and dark. Used

empiric

method to discern optimal resistor values. Schematic.

Using

new feedback capability, returned to pursuit of max res. Soon observed

the first clog. Closer inspection

reveals a tiny piece of paper (from sand bag)

lodged in orifice of nozzle. This raises the obvious need for

a filter (screen / mesh) in funnel.

Using

new feedback capability, returned to pursuit of max res. Soon observed

the first clog. Closer inspection

reveals a tiny piece of paper (from sand bag)

lodged in orifice of nozzle. This raises the obvious need for

a filter (screen / mesh) in funnel.

Nov. 7

Initial

trials to ascertain max resolution. Early results are encouraging--

able to discern 96 distinct "pixels" around circumference.

Initial

trials to ascertain max resolution. Early results are encouraging--

able to discern 96 distinct "pixels" around circumference.

Nov. 6

The

first attempt at creating a decent seal between the sand director funnel

and the inside wall of the tube using felt was clearly unacceptable.

This new design is far better. Also, have started narrowing the director's

output spout, in preparation to evaluate maximum resolution.

The

first attempt at creating a decent seal between the sand director funnel

and the inside wall of the tube using felt was clearly unacceptable.

This new design is far better. Also, have started narrowing the director's

output spout, in preparation to evaluate maximum resolution.

October, 2001:

Oct. 29

Demonstrated the full-scale prototype for Dan, Robert,

Katrina, Eugene and met Robert Hone of Red

Hill Studios. Discussed a multitude of ideas, including possible

strategies for interactivity. Notable ideas: "sand pixel" color

as indicator of sensor activation rate / splitting column of sand into

front and back, with different pattern strategies.

Plan: I will investigate the resolution limit of

the machine, in hopes of being able to faithfully recreated bitmap images

in the sand. Robert H. to begin experiments with visualizing color patterns

in a virtual environment. Tentative meeting to show results in 3

weeks (prior to Thanksgiving).

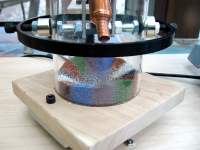

After

examining various design configurations, set to work upon the full size

prototype. Extensively utilizing my assortment of scrounged motion

control components, it came together pretty quickly.

After

examining various design configurations, set to work upon the full size

prototype. Extensively utilizing my assortment of scrounged motion

control components, it came together pretty quickly.

The acrylic tube was purchased from Crown Plastics,

and came in at $114. This is cast (vs. extruded), and although significantly

more expensive, is gorgeous. The lead screw is overkill-- but it's

the right length, and looks good. The Z-axis stepper and the Theta-axis

steppers took a while to mount-- theta has an 18:1 gearhead which is also

overkill, but since the tube will weigh in ~100lbs when full, why not.

(view

of the motor and drive layout on the underside)

To

accomplish the capping off of the tube's ends, I enlisted the use of my

CNC router. Using a 1/8" end mill, and a 3-15/16" diameter circular

path, resulted in a perfect fit.

To

accomplish the capping off of the tube's ends, I enlisted the use of my

CNC router. Using a 1/8" end mill, and a 3-15/16" diameter circular

path, resulted in a perfect fit.

After testing the two axes, and mounting the top tube

holder / lazy susan, turned attention to the magnetically coupled sand

director. After toying with a number of strategies, I decided to

follow the simplest: a funnel, a 45 degree copper coupling, and a

handful of nuts and bolts. Plus two rare-earth mags.

While a number of improvements will be made, this works reasonably well!

Because

of time constraints (I leave for NYC on 10/24), I have stolen

the maquette's sand delivery system for testing of the full size proto.

There are some sand leaks around the funnel, but the initial tests look

great.

Because

of time constraints (I leave for NYC on 10/24), I have stolen

the maquette's sand delivery system for testing of the full size proto.

There are some sand leaks around the funnel, but the initial tests look

great.

September 12, 2001

Met with Dan, Katrina, Robert and Bart. Prelim

design presented, along with weights and estimated costs of various tube

lengths and diameters. 6' length and 4" diameter agreed upon for

first full scale testing. Full scale, functional prototype to be

accomplished by end of October.

May 25, 2001

Proposal accepted.

May 23, 2001

Presented the stratograph maquette.

April-May, 2001

Development and testing of ideas. Concerns about

practicality of teardown and setup inherent in a traveling exhibit prompted

idea of archiving "sedimentation cores."

April 9, 2001

Received RFP.